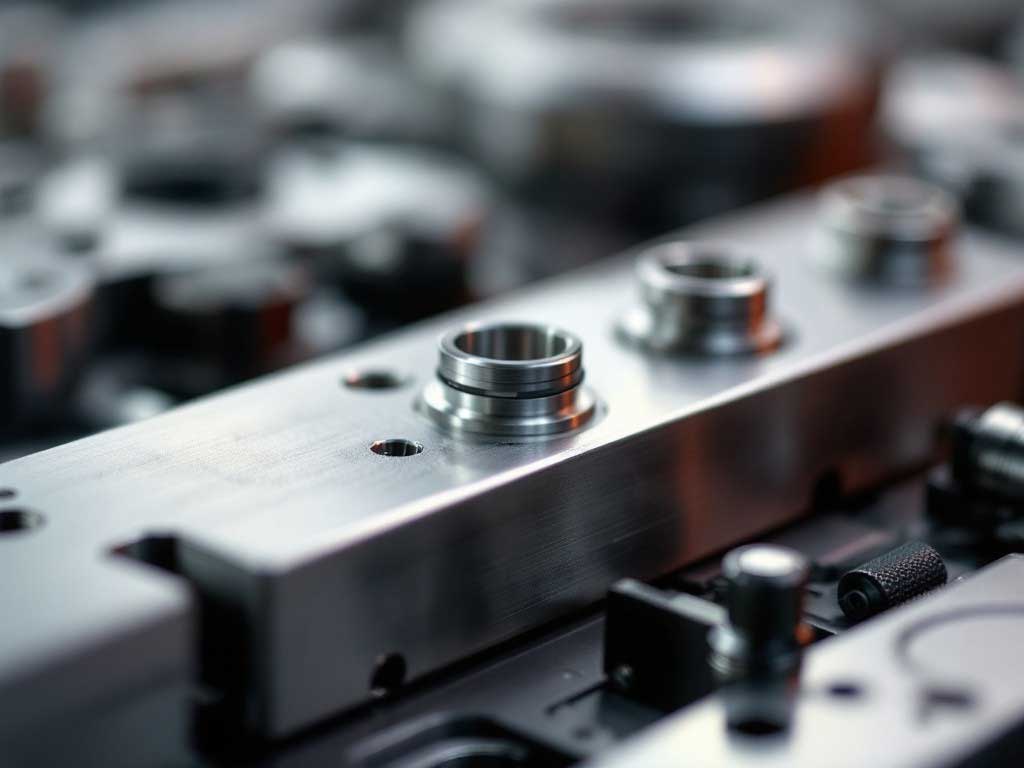

The Art of Precision in Machined Components

The art of precision in machined components revolves around achieving tight tolerances and exceptional quality in manufacturing. You utilize advanced techniques like CNC milling and turning, where machines operate within tolerances as precise as 2.5 microns. High repeatability minimizes deviations, crucial in sectors like aerospace and automotive. Exceptional surface finishes enhance the performance and durability of components. Quality control measures, including ISO certifications and statistical process control, guarantee compliance with standards. As you explore innovations like AI and additive manufacturing, you’ll discover how these trends promise to redefine precision machining and open new avenues for efficiency and creativity.

Table of Contents

Key Takeaways

- Precision machining achieves tolerances as tight as 0.0001 inches, essential for aerospace and automotive applications.

- CNC technology provides high repeatability and consistent quality across large production batches.

- Advanced processes like CNC milling and precision grinding ensure intricate shapes and superior surface finishes.

- Application across various industries includes aerospace, automotive, medical, and defense, emphasizing the importance of precision.

- Future trends like AI and Industry 4.0 enhance efficiency and quality control in precision machining practices.

Understanding Precision Machining

Understanding precision machining is crucial for grasping how complex components are manufactured with high accuracy. This process primarily employs CNC machines to remove material from solid blocks, allowing for the production of intricate parts that meet tight tolerances.

Each CNC technique, whether milling, turning, precision grinding, or EDM, is tailored for specific applications and material types, contributing to the versatility of precision machining. Achieving high tolerances, often as tight as 0.0001 inches, is essential in industries like aerospace, where performance and reliability are paramount high tolerances.

In sectors like aerospace and medical devices, the reliability of components is critical; therefore, precision machining is indispensable. The ability to achieve exceptional surface finishes not only enhances aesthetic appeal but also guarantees peak performance in demanding environments.

Additionally, the advantages of high repeatability and reduced production costs make precision machining a favored choice for manufacturers.

Quality control is a cornerstone of this process. Implementing ISO certifications and utilizing coordinate measuring machines (CMM) for dimensional inspections assures that machined components consistently meet rigorous specifications.

Key Processes and Techniques

In precision machining, several key processes and techniques play a pivotal role in shaping components with accuracy and efficiency. By utilizing advanced technology and an unwavering attention to detail, you can guarantee the production of intricate parts and complex geometries.

The integration of technological advancements like CNC machining and AI enhances the precision and speed of these processes. Here are four essential machining processes to contemplate:

- CNC Milling: This process employs rotary cutters to create intricate shapes, allowing for the production of complex geometries in machined components.

- CNC Turning: By rotating the workpiece, CNC turning produces cylindrical shapes and threads, which are essential for components like shafts and bushings.

- Precision Grinding: To achieve tight tolerances and superior surface finishes, precision grinding can reach tolerances as precise as 2.5 microns (+/-.0001), guaranteeing accuracy in every detail.

- Electrical Discharge Machining (EDM): This technique uses controlled electrical discharges to shape hard metals without direct contact, making it ideal for intricate designs in tough materials.

Benefits of Precision Machining

Precision machining offers numerous benefits that considerably enhance the quality and performance of machined components. By enabling the production of complex and intricate parts with tolerances as tight as 2.5 microns, you guarantee a perfect fit for essential applications. High accuracy is imperative, especially in the automotive industry, where matching original design specifications with negligible deviations is significant.

Utilizing advanced computer numerical control (CNC) technology, precision machining delivers high repeatability, guaranteeing consistent quality across large production batches. This reliability is indispensable when manufacturing engine components that must perform under demanding conditions.

Moreover, precision machining techniques like grinding and lapping achieve superior surface finishes, enhancing both performance and durability. The versatility in material selection allows you to accommodate a wide range of metals, plastics, and composites, broadening its applications across various industries.

Here’s a summary of the key benefits:

| Benefit | Description | Impact on Performance |

|---|---|---|

| Tight Tolerances | Parts with tolerances as tight as 2.5 microns | Guarantees perfect fit in applications |

| High Accuracy | Negligible deviations from design specifications | Essential for automotive and aerospace |

| Consistent Quality | High repeatability with CNC technology | Reliability across production batches |

| Superior Surface Finishes | Techniques like grinding enhance durability | Improved performance of components |

| Versatile Material Selection | Accommodates various materials | Broadened application potential |

Applications Across Industries

Leveraging advanced manufacturing techniques, precision machining is integral to a variety of industries, providing essential components that uphold safety and performance standards.

In aerospace, precision machining contributes to the production of components that meet strict tolerance specifications, guaranteeing operational reliability and safety. You’ll find that precision machining yields intricate parts essential for functionality and reliability across sectors.

Here are some key applications:

- Aerospace: Precision machining produces critical components like turbine blades and engine parts, which require tight tolerances for safe and reliable operation.

- Automotive: In this sector, precision machining is key for manufacturing safety-critical parts, including brakes and steering systems, that must meet stringent specifications for peak performance and longevity.

- Medical Industry: The medical sector relies on precision machining for creating implants, surgical instruments, and diagnostic equipment, all needing exacting standards for compatibility and effectiveness.

- Electronic Manufacturing: Here, precision machining plays a role in producing circuit boards and connectors, where accuracy is essential for the functionality of compact, high-performance devices.

Additionally, industries such as defense utilize precision machined components to guarantee equipment reliability and performance, which is critical for mission-critical applications in challenging environments.

Quality Control Measures

Quality control measures are essential in precision machining to assure every component meets rigorous standards. Adhering to ISO certifications guarantees that manufacturers comply with international quality benchmarks throughout the production process. To monitor and improve quality, you’ll often use statistical process control (SPC) techniques. These methods allow you to identify variations in manufacturing, maintaining consistent quality across all components.

Dimensional inspections are critical and are routinely executed using coordinate measuring machines (CMM). These inspections verify that machined components conform to specified tolerances and dimensions. Alongside this, visual inspections conducted at various production stages help catch defects early, enhancing quality assurance and minimizing defective parts.

Incorporating Six Sigma methodologies facilitates continuous improvement, focusing on reliability and accuracy to aim for zero defects in machined components. Here’s a quick overview of the quality control measures:

| Quality Control Measure | Purpose | Tools Used |

|---|---|---|

| Dimensional Inspections | Verify tolerances | Coordinate Measuring Machines |

| Visual Inspections | Identify defects early | Manual or Automated Vision |

| Statistical Process Control | Monitor process consistency | Statistical Analysis Software |

Future Trends in Machining

The future of machining is being shaped by cutting-edge technologies and innovative practices that promise to revolutionize the industry. As you look ahead, consider how the integration of these advancements will elevate precision machining:

- Artificial intelligence (AI) will enhance predictive maintenance, reducing downtime and increasing manufacturing efficiency. This integration aligns with the growing trend of technological advancements that are streamlining operations and improving productivity across various sectors.

- Additive manufacturing combined with traditional machining techniques will enable the production of intricate parts and complex geometries that were previously unattainable.

- The rise of advanced materials, like composites and high-performance alloys, will demand precision machining capabilities to handle unique material properties and complex shapes.

- Principles of Industry 4.0, including the Internet of Things (IoT) and smart manufacturing, will facilitate real-time data collection and analysis, optimizing production workflows and quality control.

Moreover, sustainable machining practices will gain traction, focusing on reducing waste and energy consumption through innovative technologies.

Conclusion

In the world of precision machining, you’d think that perfection is the goal. Ironically, the pursuit of absolute accuracy often leads to innovation and creativity. By mastering key processes and embracing quality control, you’re not just crafting components; you’re shaping the future of industries. So, while aiming for flawlessness, remember that it’s the very imperfections and challenges that drive progress. Embrace the art of precision, and who knows? You might just redefine what it means to be ‘precise.’