What Is a Forged Crankshaft and Its Importance?

A forged crankshaft is an essential engine component that converts the linear motion of pistons into rotational motion. Made from a single piece of high-quality steel alloy and shaped through a meticulous forging process, it boasts superior strength and fatigue resistance compared to cast alternatives. This durability allows it to withstand high stress and deliver more consistent performance, vital for high-performance and motorsport applications. Additionally, its lighter design improves engine efficiency, responsiveness, and longevity. If you’re interested in how these factors enhance overall engine performance, you’ll find more insights on the topic.

Table of Contents

Key Takeaways

- A forged crankshaft is a single-piece engine component that converts linear motion into rotational motion with enhanced material strength.

- Its manufacturing process involves forging, machining, and heat treatment to ensure durability and optimal performance.

- Forged crankshafts offer superior fatigue resistance, making them less prone to failure under high stress and extreme conditions.

- They are lighter than cast crankshafts, improving engine efficiency, responsiveness, and overall performance.

- Widely used in motorsport and high-performance vehicles, they contribute to engine longevity and reliability.

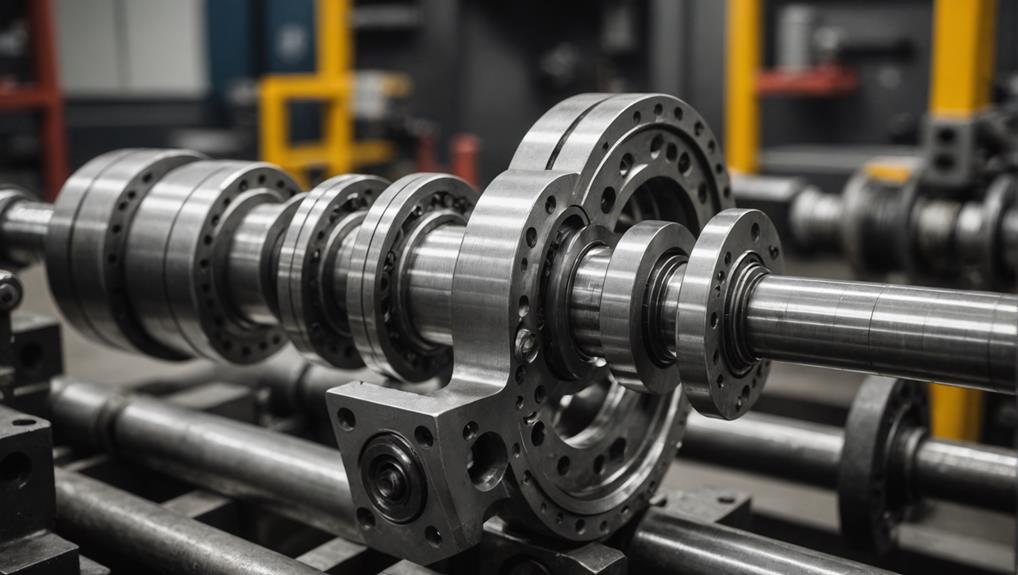

Definition of Forged Crankshaft

A forged crankshaft is an important component in an engine, designed to convert the linear motion of the pistons into rotational motion. Its primary function is to transfer power generated during combustion to the drivetrain, making it essential for vehicle operation.

The forging process enhances the material properties of the crankshaft, resulting in superior strength and durability compared to cast alternatives. This improvement in material integrity is significant for understanding the importance of industrial crankshafts, as it allows for better performance under high-stress conditions.

When considering a forged crankshaft, you must pay attention to various design considerations. The overall geometry, including the dimensions and weight distribution, plays a significant role in the crankshaft’s performance. A well-designed crankshaft minimizes vibration and guarantees smooth operation, preventing premature wear on engine components.

Material selection is another key aspect. Typically, high-strength steel alloys are used due to their excellent fatigue resistance and ability to withstand the extreme forces encountered during engine operation. The material properties, such as tensile strength and elongation, directly impact the crankshaft’s longevity and reliability.

Additionally, you should consider the specific application of the crankshaft. High-performance engines may require specialized designs to handle increased power outputs, necessitating more rigorous material properties and precise engineering.

Manufacturing Process

The manufacturing process of a forged crankshaft is fundamental to achieving the high strength and durability necessary for ideal engine performance. This process involves several significant steps that guarantee the crankshaft meets the stringent requirements of modern engines.

Importantly, understanding the specific material properties and manufacturing techniques used in crankshaft production in India can provide insights into how these components are tailored for various applications.

Here’s a breakdown of the key stages:

- Material Selection: Choosing the right material is essential. High-quality steel alloys are commonly used due to their superior strength-to-weight ratio and fatigue resistance.

- Forging: The selected material undergoes a forging process, where it’s heated to a malleable state and shaped under high pressure. This step aligns the grain structure of the metal, enhancing its overall strength.

- Machining: After forging, the crankshaft is precisely machined to achieve the desired dimensions and surface finish. This step is critical for guaranteeing proper fit and function within the engine.

- Heat Treatment: Finally, the crankshaft undergoes heat treatment. This process enhances hardness and wear resistance, essential attributes for withstanding engine stresses.

Through these stages, you guarantee that the forged crankshaft not only meets but exceeds performance expectations.

Each step, from material selection to heat treatment, plays a pivotal role in developing a crankshaft that can endure the rigorous demands of high-performance engines.

Understanding this manufacturing process allows you to appreciate the engineering excellence behind forged crankshafts, setting them apart in the automotive industry.

Advantages of Forged Crankshafts

When it comes to engine performance, forged crankshafts offer several advantages that set them apart from their cast counterparts. One of the primary benefits you’ll notice is their durability.

Forged crankshafts are produced through a process that aligns the grain structure of the metal, resulting in a component that’s much stronger and less prone to failure under stress. This durability benefit not only extends the life of the crankshaft but also enhances the overall longevity of your engine. Many top crankshaft manufacturers in India emphasize the importance of using forged crankshafts in high-performance applications.

Additionally, you’ll appreciate the weight reduction that forged crankshafts provide. While maintaining structural integrity, they can be designed to be lighter than cast alternatives.

This reduction in weight translates to improved engine efficiency, as a lighter crankshaft can help your engine rev quicker and reduce rotational mass. The enhanced responsiveness you experience can lead to better acceleration and overall performance.

Moreover, forged crankshafts often exhibit superior fatigue resistance. This means that under high-performance conditions—such as racing or heavy towing—they’re less likely to develop cracks or deform.

This resilience is essential for maintaining ideal engine function during demanding scenarios.

Comparison With Cast Crankshafts

Forged crankshafts markedly outperform cast crankshafts in several vital areas. When considering the differences, you’ll notice that forged durability is a significant factor. This durability comes from the forging process, which aligns the metal’s grain structure and enhances its strength. In contrast, cast crankshafts often have inconsistencies in their material properties due to the casting process, making them less reliable under stress.

Additionally, understanding industrial crankshafts reveals that the manufacturing techniques can greatly influence overall engine performance.

Here are four key areas where forged crankshafts excel compared to their cast counterparts:

- Strength-to-Weight Ratio: Forged crankshafts often achieve a better strength-to-weight ratio, allowing for lighter designs without compromising strength.

- Fatigue Resistance: The forging process results in a more uniform material structure, providing superior fatigue resistance over time, which is essential in high-performance applications.

- Impact Resistance: Forged crankshafts can better withstand sudden shocks and impacts, ensuring longevity and reliability under extreme conditions.

- Performance Consistency: The manufacturing process of forged crankshafts leads to more consistent performance characteristics, making them a preferred choice for high-performance engines.

In a weight comparison, forged crankshafts can be lighter yet stronger than cast crankshafts, providing engineers with the flexibility to design engines that perform better while maintaining lower overall weight.

This combination of strength, durability, and weight efficiency makes forged crankshafts an indispensable component in high-performance engine designs.

Impact on Engine Performance

Engine performance hinges considerably on the quality and construction of its components, with crankshafts playing a critical role. When you opt for a forged crankshaft, you’re directly impacting both engine durability and power delivery. These components are engineered to endure higher stress levels, reducing the risk of failure during intense operation.

Here’s a concise overview of how forged crankshafts affect performance:

| Feature | Forged Crankshaft | Cast Crankshaft |

|---|---|---|

| Strength | High tensile strength | Lower tensile strength |

| Weight | Generally lighter | Heavier |

| Flexibility | Low flexibility (stiff) | Higher flexibility |

| Engine RPM Capacity | Higher RPM capability | Limited RPM capacity |

| Vibration Resistance | Superior resistance | Lower resistance |

With these distinctions, forged crankshafts provide enhanced power delivery. They allow your engine to operate at higher RPMs without compromising performance, thanks to their superior strength and lower weight. This means your vehicle can handle more horsepower, translating to better acceleration and overall responsiveness.

Moreover, the durability of forged crankshafts means that they can withstand the rigors of high-performance applications, making them a favorite among motorsport enthusiasts. By investing in a forged crankshaft, you’re not just enhancing your engine’s performance but also ensuring longevity and reliability.