Key Features of Industrial Crankshafts in India

Industrial crankshafts in India are essential for converting linear motion into rotational energy, ensuring efficient power transfer in heavy-duty machinery. You’ll find that they’re engineered with precise geometries to optimize balance and minimize wear. Typically made from cast iron or alloy steels, these crankshafts withstand high torque loads and provide excellent durability. Advanced CNC machining and heat treatment techniques enhance their mechanical properties, while regular maintenance is key to prolonging lifespan. Adhering to strict quality standards guarantees performance and reliability. Understanding these features further illuminates the advancements shaping the industry today.

Table of Contents

Key Takeaways

- Industrial crankshafts convert linear motion into rotational energy, crucial for the efficient operation of machinery and engines across various sectors.

- They are designed to endure high torque loads and significant stress, ensuring durability in heavy-duty applications.

- Common materials include cast iron for wear resistance and alloy steels for strength, influencing overall performance and maintenance costs.

- Advanced manufacturing techniques, like CNC machining and heat treatment, enhance precision, durability, and performance standards of crankshafts.

- Regular inspections and adherence to quality standards are vital for maintaining optimal performance and preventing operational failures in industrial applications.

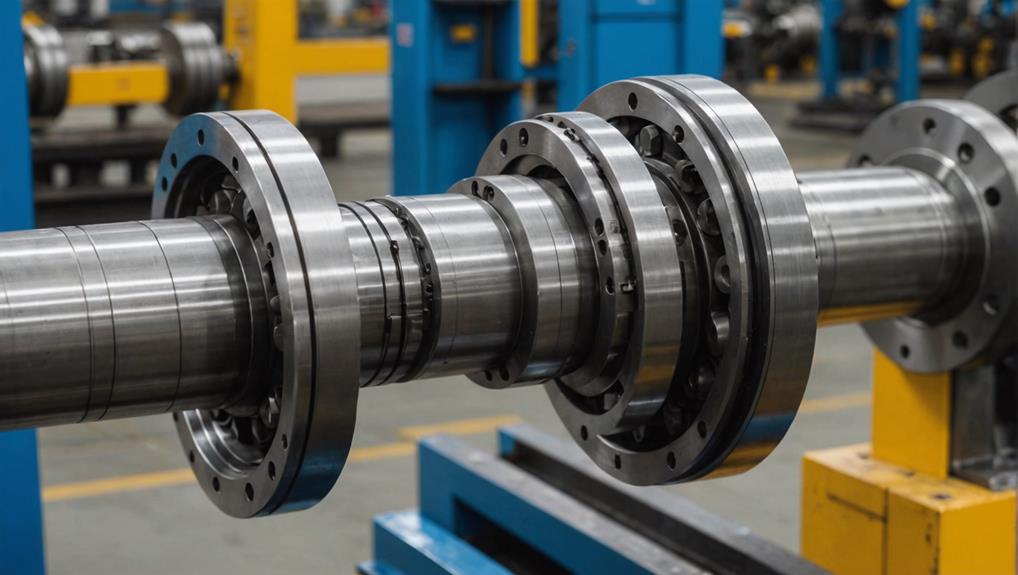

Importance of Industrial Crankshafts

Industrial crankshafts play an important role in converting linear motion into rotational energy, making them essential components in various machinery and engines. Their significance extends across multiple industrial applications, where they facilitate the efficient transfer of power.

As you explore the workings of engines, you’ll realize that crankshafts are fundamental for transforming the reciprocating motion of pistons into the rotational motion required to drive machinery. Understanding crankshaft functionality is essential for enhancing engine performance and guaranteeing the longevity of industrial equipment.

In heavy-duty machinery, such as generators and compressors, crankshafts endure significant stress and must exhibit high durability. This durability guarantees reliable operation, minimizing downtime and maintenance costs.

The crankshaft’s ability to withstand high torque loads is imperative, especially in applications involving mechanical power transmission.

In automotive engines, crankshafts are key to achieving peak engine performance and efficiency. The precision with which they’re manufactured affects fuel efficiency and overall vehicle performance.

It’s not just about generating power; it’s also about how effectively that power is harnessed and used.

Moreover, in industrial applications like marine engines or power generation systems, the crankshaft’s design influences overall system efficiency and output. A well-engineered crankshaft can lead to enhanced performance metrics, such as reduced fuel consumption and lower emissions.

Understanding the significance of crankshafts in these applications underscores their pivotal role in the broader context of industrial engineering. Without these components, many machines and engines simply wouldn’t function as efficiently or effectively as they do today.

Design Specifications

When considering the design specifications of crankshafts, several key factors come into play that directly influence their performance and reliability. First and foremost, you need to focus on the geometry of the crankshaft. This includes the stroke length, throw radius, and the arrangement of counterweights, all of which must be meticulously calculated to minimize vibrations and guarantee smooth operation.

Properly designed crankshafts can lead to improved fuel efficiency and lower emissions, which are essential in today’s industrial applications understanding industrial crankshafts.

Next, you should consider the balance of the crankshaft. An unbalanced crankshaft can lead to excessive wear and tear on the engine components. Achieving ideal balance often involves design innovations that incorporate advanced computational modeling techniques, allowing for precise adjustments.

Moreover, the design must address engineering challenges related to torque and power transfer. Crankshafts must be engineered to withstand high torsional loads while maintaining structural integrity. This involves a careful selection of dimensions and features like fillets to reduce stress concentration points.

You’ll also want to evaluate the bearing surfaces. These surfaces must be designed for low friction and high wear resistance, often necessitating intricate surface treatments or texturing.

Materials Used

Selecting the right materials for crankshafts is crucial for optimizing their performance and durability. The choice of materials directly impacts the crankshaft’s ability to withstand high stresses and resist fatigue over time. In the industrial sector, common materials include cast iron and various alloy types, each offering distinct advantages depending on the application. Significantly, many leading crankshaft manufacturers in India utilize advanced materials to enhance the operational efficiencies of their products.

Cast iron is widely used due to its excellent wear resistance and good machinability. It effectively absorbs vibrations, which contributes to smoother operation. However, for applications requiring higher strength-to-weight ratios, you might consider alloy steels, which can provide enhanced mechanical properties. These alloy types, such as 4140 and 4340, are particularly favored for their toughness and fatigue resistance.

When it comes to manufacturing processes, the choice of casting methods plays a critical role. Sand casting is prevalent for producing crankshafts, as it allows for complex geometries and is cost-effective for low to medium production volumes. Alternatively, you could explore investment casting for more intricate designs, although it typically incurs higher production costs.

The selection of materials and casting methods isn’t just about immediate performance; it also affects long-term maintenance and operational costs. For instance, while lighter alloys may improve efficiency, they might necessitate more frequent inspections and replacements, impacting overall reliability.

Therefore, understanding the interplay between materials and specific application requirements is essential for ensuring that the crankshaft meets both performance and durability expectations in demanding industrial environments.

Manufacturing Techniques

Manufacturing techniques for crankshafts are vital in determining their performance and longevity. When you look at the production process, CNC machining stands out as a fundamental technique. This technology allows for precise shaping of crankshaft components, guaranteeing that tolerances are maintained within strict limits.

It’s important that you employ advanced CNC equipment, as even minor deviations can lead to significant performance issues. The use of precision CNC machining services not only enhances the accuracy but also streamlines the production process, contributing to reduced lead times and costs.

Following machining, heat treatment plays a significant role in enhancing the mechanical properties of the crankshaft. By subjecting the material to controlled heating and cooling cycles, you can improve its hardness and durability. This step is necessary for confirming the crankshaft can withstand the high stresses encountered during operation.

Surface finishing comes next and is equally important. Techniques such as grinding, polishing, and shot peening are employed to create a smooth surface. A well-finished crankshaft reduces friction and wear, which directly impacts its lifespan. You must focus on achieving the best surface roughness to enhance compatibility with engine components.

Quality assurance should be integrated throughout the manufacturing process. Implementing rigorous inspection protocols at each stage, from CNC machining to final surface finishing, guarantees that any deviations from specifications are identified and corrected.

Performance Characteristics

When evaluating industrial crankshafts, you’ll want to focus on torque and power output, as these directly impact engine efficiency and performance.

Additionally, understanding the manufacturing processes and quality control measures used in crankshaft production in India is essential for guaranteeing high standards.

Consider the material strength and durability, which are vital for long-term operation under extreme conditions.

Torque and Power Output

Understanding torque and power output is vital for evaluating the performance characteristics of industrial crankshafts, as these metrics directly influence the engine’s efficiency and overall functionality.

Torque enhancement plays a significant role in guaranteeing that the crankshaft can effectively convert the engine’s rotational force into usable mechanical energy. By maximizing torque, you enhance the engine’s ability to perform under varying load conditions, which is essential in industrial applications where heavy-duty performance is often required.

Power efficiency, on the other hand, relates to how effectively the engine converts fuel into power. When you have a crankshaft designed for peak power output, you minimize energy loss and guarantee that more energy is used for driving mechanical processes rather than being wasted as heat or vibration.

A well-enhanced crankshaft will balance torque and power output, allowing for smoother engine operation and improved overall performance.

Material Strength and Durability

Evaluating the material strength and durability of industrial crankshafts is essential for their performance and longevity in demanding environments. You’ll find that two critical properties—fatigue resistance and tensile strength—play pivotal roles in determining how well a crankshaft withstands operational stress over time.

| Property | Importance |

|---|---|

| Fatigue Resistance | Guarantees the crankshaft can endure cyclic stress without failure, enhancing overall reliability. |

| Tensile Strength | Determines the maximum load the crankshaft can bear, preventing deformation or breakage under heavy operational loads. |

Choosing the right materials, such as high-carbon steel or alloyed steel, greatly impacts these properties. By focusing on both fatigue resistance and tensile strength, you can guarantee that the crankshaft performs efficiently under heavy workloads and variable conditions. Monitoring these characteristics not only improves operational efficiency but also reduces maintenance costs and prolongs the lifespan of the machinery. When selecting crankshafts, prioritize these material properties to enhance performance and reliability in your industrial applications.

Vibration and Noise Levels

Material strength and durability directly influence vibration and noise levels in industrial crankshafts. When you evaluate a crankshaft’s performance, consider how its material composition affects its ability to withstand operational stresses without excessive deformation. A robust crankshaft minimizes vibrations, which can lead to increased wear and tear and potential failure.

Conducting vibration analysis is essential in diagnosing performance issues. By identifying specific vibration patterns, you can determine if the crankshaft is operating within acceptable limits. High vibration levels often indicate misalignment, imbalance, or structural weaknesses, which can exacerbate noise issues.

Implementing effective noise reduction strategies is vital for ensuring compliance with industry standards and enhancing operator comfort. Techniques such as optimizing the geometry of the crankshaft and using advanced materials can greatly lower noise emissions.

Additionally, incorporating damping materials can further mitigate vibrations and noise, leading to improved overall performance.

Applications in Industries

Industrial crankshafts play an essential role in various sectors, powering a wide range of machines and vehicles. They’re designed to withstand tremendous forces and stresses, which is critical for guaranteeing longevity and reliability.

You’ll find their applications spanning multiple industrial sectors, each with unique demands and specifications. Understanding these crankshaft applications can help you appreciate their importance in maintaining efficiency and reliability in operations. This understanding is also enhanced by recognizing the key insights about crankshaft functionality.

Here are five key applications of industrial crankshafts:

- Automotive Industry: Crankshafts are fundamental in internal combustion engines, converting linear motion into rotational motion, essential for vehicle propulsion.

- Marine Applications: In marine engines, crankshafts drive propellers, allowing vessels to achieve ideal speed and fuel efficiency.

- Aerospace: Aircraft engines utilize crankshafts to manage power output, providing the necessary thrust for flight.

- Construction Equipment: Heavy machinery, such as excavators and bulldozers, relies on robust crankshafts to handle demanding tasks and guarantee longevity.

- Power Generation: In generators, crankshafts facilitate the conversion of mechanical energy into electrical energy, playing a critical role in energy production.

In each of these sectors, the reliability and performance of the crankshaft can greatly impact overall equipment efficiency.

As a result, when selecting crankshafts, it’s essential to evaluate the specific requirements of the application. By focusing on the right materials and designs, you can enhance the performance and durability of machinery, ultimately contributing to operational success across various industrial applications.

Quality Standards

When selecting crankshafts for various applications, adhering to quality standards is fundamental to guarantee peak performance and reliability. Quality standards play a significant role in ascertaining that the crankshafts you choose meet specific performance metrics that are essential for your operations. These metrics include tensile strength, fatigue resistance, and dimensional accuracy, which directly affect the crankshaft’s functionality and longevity.

Additionally, the benefits of forged crankshafts highlight their superior strength and durability, making them an excellent choice for demanding industrial applications.

Regulatory compliance is another important aspect. Industry regulations dictate the manufacturing processes, materials used, and testing protocols that crankshafts must undergo before they’re deemed suitable for use. By following these regulations, you minimize the risk of purchasing subpar products that could lead to operational failures or safety hazards.

It’s important to scrutinize the certifications associated with crankshaft production. Look for adherence to standards set by organizations like the Bureau of Indian Standards (BIS) or international standards such as ISO 9001. These certifications reflect a commitment to quality control and continuous improvement in manufacturing practices.

Furthermore, consider the supplier’s reputation and their track record in meeting quality standards. A reliable supplier typically invests in advanced testing equipment and employs skilled personnel to ascertain that their crankshafts meet the highest industry benchmarks.

Maintenance Considerations

To guarantee ideal performance of industrial crankshafts, you must implement regular inspection protocols.

These inspections help identify wear and potential issues before they escalate.

Additionally, adhering to lubrication best practices is essential for minimizing friction and prolonging the crankshaft’s lifespan.

Regular Inspection Protocols

Regular inspections play an essential role in maintaining the performance and longevity of crankshafts. By adhering to a structured inspection protocol, you can identify potential issues early and guarantee your equipment runs efficiently.

Incorporating advanced inspection technology into your maintenance schedules can greatly enhance the reliability of your crankshafts.

To optimize your inspection process, consider the following key practices:

- Visual Inspections: Regularly check for signs of wear, corrosion, or damage.

- Vibration Analysis: Monitor vibration patterns to detect imbalances or misalignments.

- Ultrasonic Testing: Use this technology to identify internal flaws that may not be visible externally.

- Dimensional Checks: Measure critical dimensions to guarantee they meet specifications.

- Lubricant Analysis: Regularly test lubricants for contamination and degradation.

Lubrication Best Practices

Effective lubrication is vital for the ideal performance and durability of industrial crankshafts. To achieve optimal results, you need to understand different lubrication types, including synthetic, mineral, and biodegradable oils. Each type has its advantages, and selecting the right one based on your operational conditions can greatly impact crankshaft longevity.

Regular monitoring and maintenance of oil quality are essential. Implement a robust oil filtration system to remove contaminants and guarantee that the lubricant remains clean. Contaminated oil can lead to increased wear and potential failure of the crankshaft, so check the filtration system frequently for clogs or inefficiencies.

Additionally, adhere to a scheduled oil change regimen, as the oil’s properties degrade over time. Utilize oil analysis techniques to assess viscosity, acidity, and the presence of wear particles. This data allows you to make informed decisions about lubrication intervals.

Future Trends in Crankshaft Technology

Innovation drives the evolution of crankshaft technology, with several key trends poised to reshape the industry. As you look ahead, you’ll notice that sustainability initiatives and automation advancements are at the forefront of these developments.

Manufacturers are increasingly adopting practices that not only improve efficiency but also reduce environmental impact, such as cold forging components, which enhance strength and reduce material waste.

Here are some future trends you should consider:

- Lightweight Materials: The shift toward lighter, high-strength materials is gaining momentum, improving fuel efficiency and performance.

- 3D Printing: Additive manufacturing is revolutionizing crankshaft production, allowing for complex geometries and reduced waste.

- Smart Crankshafts: Integration of IoT technology enables real-time monitoring and predictive maintenance, enhancing operational reliability.

- Eco-friendly Coatings: Development of sustainable coatings minimizes wear and enhances durability while reducing harmful emissions.

- Advanced Design Software: Innovative simulation tools are optimizing crankshaft design, ensuring peak performance with minimal material use.

These trends underscore a notable shift in how crankshafts are designed and manufactured. By embracing these advancements, you’ll not only improve product performance but also align with global sustainability goals.

Automation advancements are streamlining production processes, notably reducing lead times and costs. As you navigate these changes, staying informed and adaptable will be essential for maintaining a competitive edge in the industry.

The future of crankshaft technology is bright, and those who invest in these trends will likely reap substantial rewards.