What Are Industrial Crankshafts and How Do They Work?

Industrial crankshafts are critical components in engines and generators, transforming linear motion from pistons into rotational energy. They consist of several parts, including crankpins and main journals, which facilitate movement and balance. Made typically from robust materials like forged steel or cast iron, crankshafts guarantee durability and efficiency across various industries, such as automotive and power generation. Proper design minimizes vibrations and enhances load distribution. Maintenance is fundamental for preventing failures and optimizing performance. To uncover more about types and applications, it is important to explore deeper into their engineering and operational aspects.

Table of Contents

Key Takeaways

- Industrial crankshafts convert linear motion from pistons into rotational motion, essential for engines and generators’ functionality.

- They are typically made from high-strength materials like steel alloys or cast iron, ensuring durability and performance.

- Crankshafts consist of components such as crankpins, main journals, and connecting rods to facilitate smooth operation and energy transfer.

- Proper design minimizes stress concentrations and vibrations, enhancing machinery efficiency and longevity.

- Regular maintenance, including lubrication and alignment checks, is crucial for preventing failures and ensuring optimal performance.

Definition of Industrial Crankshafts

An industrial crankshaft is a significant component in various machinery, converting linear motion into rotational motion with precision. This transformation is fundamental in engines and generators, where efficiency and reliability are paramount. The design of a crankshaft involves careful consideration of both geometry and materials to withstand the stresses encountered during operation.

In addition, understanding crankshaft applications is imperative for optimizing performance in specific industrial settings.

When you’re looking at crankshaft design, you’ll notice that it typically features a series of offsets, or throws, which align with the pistons in the engine. This design allows for smooth operation and effective power delivery. Its shape and dimensions are meticulously calculated to optimize performance while minimizing vibration and wear.

Crankshaft materials play an essential role in guaranteeing the component’s durability and functionality. High-strength steel alloys are commonly used due to their superior tensile strength and fatigue resistance. In some cases, cast iron may be employed for its excellent wear characteristics, particularly in lower-stress applications.

The choice of material directly influences the crankshaft’s ability to handle high loads and temperatures, consequently impacting overall machine performance.

As you explore deeper into the specifics, you’ll find that advanced manufacturing techniques, such as forging and machining, further enhance the properties of crankshafts. These processes guarantee precise tolerances and surface finishes, contributing to the longevity and efficiency of the machinery.

Understanding the interplay between crankshaft design and materials is fundamental for anyone involved in industrial applications, as it directly affects operational effectiveness.

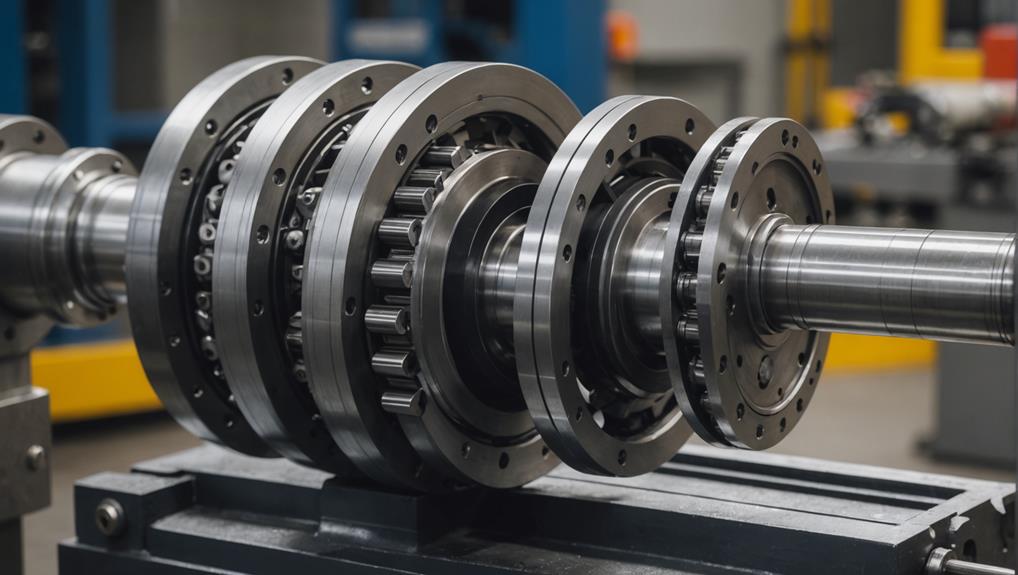

Components of Crankshafts

When examining the components of crankshafts, you’ll notice several vital elements that work together to secure peak performance. The primary component is the crankshaft itself, which transforms linear motion from pistons into rotational motion. The crankshaft’s design is essential; it features various journal bearings and counterweights that balance forces during operation. One of the significant advantages of using a forged crankshaft is its enhanced strength and resistance to fatigue, which is important in high-performance applications understanding the benefits of forged crankshafts.

Next, you’ll find the main journals and crankpins. The main journals support the crankshaft within the engine block, while crankpins connect to the connecting rods, transferring force from the pistons. These elements must be precisely engineered to minimize friction and wear, guaranteeing longevity.

Crankshaft materials also play a significant role in performance. Typically, you’ll encounter forged steel or cast iron crankshafts, chosen for their strength and durability. Advanced materials like aluminum or high-performance alloys are used in specialized applications to reduce weight without sacrificing strength.

Additionally, the crankshaft’s design often incorporates features like fillets and radii to reduce stress concentrations, enhancing overall resilience. The surface finish is equally important; a finely honed finish decreases friction, improving efficiency and longevity.

Lastly, keyways and thrust washers secure proper alignment and prevent lateral movement. Each of these components and considerations are integral to achieving ideal performance and reliability in an industrial crankshaft.

Understanding these elements gives you insight into the complexity and engineering excellence behind these vital engine components.

How Crankshafts Function

Crankshafts play an essential role in converting the linear motion of pistons into the rotational energy needed to power an engine. This transformation is critical for engine efficiency and heavily relies on effective crankshaft design. When the pistons move up and down within the cylinders, they generate linear force. The crankshaft captures this force and translates it into rotational movement, allowing the engine to function smoothly.

Here’s how crankshafts achieve this transformation:

- Piston Movement: As the pistons move down during the power stroke, they exert force on the connecting rods attached to the crankshaft.

- Crankshaft Rotation: The connecting rods push against the crankpins on the crankshaft, causing it to rotate. The design of the crankshaft guarantees that this rotation is as effective as possible, minimizing energy loss.

- Power Transmission: The rotational energy produced is then transmitted to the engine’s flywheel, which helps maintain momentum and stabilize engine operation.

The efficiency of an engine is considerably influenced by crankshaft design. A well-engineered crankshaft minimizes vibrations and maximizes torque output, which is essential for ideal performance.

Poor crankshaft design can lead to excessive wear and tear, reducing engine efficiency and longevity. As a result, understanding how crankshafts function is critical for anyone involved in engine design and maintenance, as it directly impacts overall vehicle performance.

Types of Industrial Crankshafts

When selecting an industrial crankshaft, you’ll encounter several types, each with distinct advantages.

Crankshafts manufactured in India often showcase a variety of materials and designs tailored to specific industrial needs, including understanding crankshafts that highlight regional manufacturing strengths.

Forged steel crankshafts offer exceptional strength and durability, while cast iron crankshafts provide cost-effective solutions for lower-stress applications.

Lightweight aluminum crankshafts are ideal for reducing overall engine weight, enhancing performance in specific environments.

Forged Steel Crankshafts

Forged steel crankshafts are essential components in many industrial applications, renowned for their strength and durability.

Their robust construction makes them ideal for high-performance environments, where reliability is paramount. The manufacturing process involves shaping steel under extreme pressure, enhancing its molecular structure and, consequently, its tensile strength.

Here are three key forged benefits you should consider:

- Higher Strength-to-Weight Ratio: Forged steel crankshafts provide significant strength while maintaining a lighter weight, which improves overall engine efficiency.

- Improved Fatigue Resistance: The forging process aligns the grain structure of the steel, resulting in better resistance to fatigue. This is vital for applications with high cyclic loads.

- Enhanced Wear Resistance: The dense nature of forged steel minimizes the likelihood of wear and tear, extending the lifespan of the crankshaft and reducing maintenance costs.

Cast Iron Crankshafts

How do cast iron crankshafts stack up against their forged counterparts in industrial applications?

Cast iron crankshafts leverage specific cast iron properties that can make them ideal for certain environments. With high wear resistance and excellent damping capabilities, cast iron effectively absorbs vibrations, which can lead to smoother operation in heavy machinery.

One of the primary cast iron advantages is its cost-effectiveness. Manufacturing processes for cast iron crankshafts are typically less expensive than forging, allowing you to reduce production costs without compromising quality.

Additionally, the inherent strength of cast iron allows it to endure significant loads, making it suitable for various industrial applications.

Another significant property is the ability of cast iron to be easily machined and cast into complex shapes, which can be essential for customizing crankshafts to specific requirements.

Moreover, cast iron’s thermal stability enhances its performance under high-temperature conditions.

Lightweight Aluminum Crankshafts

In industrial applications where weight reduction is essential, lightweight aluminum crankshafts emerge as a considerable alternative to traditional materials. These crankshafts offer several lightweight benefits that enhance performance, particularly in sectors demanding efficiency and speed.

- Weight Reduction: Aluminum crankshafts reduce overall engine weight, leading to improved fuel efficiency and increased power-to-weight ratios.

- Corrosion Resistance: Aluminum’s innate resistance to corrosion enhances durability, making it suitable for various aluminum applications, especially in harsh environments.

- Thermal Conductivity: Aluminum dissipates heat more effectively than other materials, aiding in maintaining ideal operating temperatures.

Utilizing lightweight aluminum crankshafts can lead to better engine performance and longevity.

They’re particularly beneficial in industries like aerospace, automotive, and marine, where every ounce counts.

By choosing aluminum crankshafts, you’ll not only streamline your operations but also embrace advanced engineering solutions.

Their integration into your machinery can greatly influence overall productivity, making them a smart choice for modern industrial applications.

Applications in Various Industries

Industrial crankshafts play a vital role in various sectors, including manufacturing, marine, and power generation.

They’re essential components in engines and machinery, and leading crankshaft manufacturers in India guarantee high-quality production standards.

In manufacturing and production, they secure efficient operation of machinery, while in marine applications, they facilitate the propulsion of vessels.

Additionally, in power generation, crankshafts contribute to the reliable functioning of engines that drive electrical generators.

Manufacturing and Production

Crankshafts play an essential role in the manufacturing and production processes across various industries.

These components are integral to converting linear motion from pistons into rotational motion, which is critical for machinery operation. Understanding how crankshafts fit into your production processes can enhance efficiency and reliability.

Here are three key applications of crankshafts in manufacturing:

- Automotive Industry: In automotive engines, crankshafts facilitate the combustion cycle, guaranteeing peak engine performance. Their design and precision directly influence fuel efficiency and emissions.

- Heavy Machinery: In construction and agricultural equipment, crankshafts provide the necessary power for hydraulic systems and other operational functions. Their durability is essential for sustaining heavy loads and prolonged use.

- Aerospace Applications: Aerospace manufacturing employs crankshafts in turbine engines, where they support high-speed operations and reliability under extreme conditions.

Advanced manufacturing techniques make certain that these components meet strict safety standards.

Marine and Power Generation

Throughout various industries, crankshafts are fundamental for marine and power generation applications. In marine engines, they convert linear motion from pistons into rotational motion, powering vessels efficiently. The design of these crankshafts must withstand high torque and vibration levels, ensuring reliability and performance in diverse marine environments. Their strength and durability are essential, as failure could lead to catastrophic consequences.

In power generation, crankshafts play an important role in converting energy from combustion into mechanical energy, driving generators that produce electricity. The specifications for these crankshafts often include materials that can endure high temperatures and pressures, maintaining structural integrity over long operational periods.

Additionally, precision machining is crucial to minimize friction and wear, thereby enhancing efficiency.

You’ll find that the integration of advanced materials and engineering techniques greatly improves the performance of crankshafts in both marine and power generation applications. By focusing on optimizing weight, strength, and fatigue resistance, manufacturers can meet the demanding requirements of these sectors.

Understanding these aspects empowers you to appreciate the essential role crankshafts play in ensuring reliability and efficiency in marine engines and power generation systems.

Importance in Machinery Performance

In modern machinery, the role of crankshafts is fundamental for achieving peak performance. These components convert linear motion into rotational energy, ensuring that your machinery operates smoothly and efficiently.

Properly designed crankshafts contribute markedly to performance optimization and vibration reduction, both of which are essential for maintaining the longevity of equipment and enhancing overall productivity.

Understanding crankshafts is vital for engineers and technicians, as it allows for better design and implementation in various machinery applications.

Here are three key reasons why crankshafts are vital in machinery performance:

- Energy Efficiency: A well-engineered crankshaft minimizes energy losses during the conversion process. This efficiency translates to lower fuel consumption and reduced operational costs, allowing you to maximize your output while minimizing expenses.

- Vibration Control: Crankshafts are designed to balance forces and reduce vibrations. By maintaining stability, they prevent excessive wear on other components, which can lead to costly repairs and downtime. A balanced crankshaft promotes smoother operation, enhancing both performance and reliability.

- Load Distribution: Crankshafts facilitate even load distribution across the engine or machinery system. This characteristic prevents localized stress concentrations, reducing the risk of component failure and ensuring consistent performance over time.

Maintenance and Longevity Tips

Maintaining your machinery’s crankshaft in prime condition is essential for its longevity and performance. To achieve this, implementing a structured preventive maintenance program is significant. Regular inspections help you identify wear and tear early, allowing for timely interventions.

Check for any signs of misalignment or unusual vibrations, as these can indicate underlying issues that could compromise the crankshaft’s integrity.

Lubrication techniques play an important role in maintaining crankshaft health. Verify you’re using the appropriate lubricant type and viscosity recommended by the manufacturer. Over time, oil can degrade or become contaminated, reducing its effectiveness.

Establish a routine for oil changes, and take care to monitor oil levels regularly. Using a high-quality lubricant not only minimizes friction but also protects against corrosion and wear.

Consider temperature management as well. Excessive heat can lead to thermal expansion and stress on the crankshaft. Installing cooling systems, such as oil coolers, can help maintain ideal operating temperatures.

Additionally, verify that the crankcase is adequately ventilated to prevent overheating.

Lastly, maintain proper balance and alignment of your machinery. Imbalances can lead to unnecessary stress and wear on the crankshaft.

Regularly calibrate and align components as part of your maintenance routine to prevent these issues.